Posted by Beren McKay on Oct 14th 2023

FACTORY CONVINCED BY THE SUBTLE YET SOLID MERINO

In order to solve the impossible or to improve on perfection you have to step outside the conventional and have the fortitude to dare to do something different.

When I first shared these new knife designs with the manufacturing factory they had doubts because the construction of these knives was so different than the norm. No amount of mathematical proof would change their perspective and so while I was there on site with them, I suggested that we use thier accredited testing lab and run these new knives through a gauntlet of knife tests.

The next day I was shocked to discover a crowd of 30 people in the lab. Turns out the heads of production, assembly, engineering and several other elements of the factory were deeply interested in how my knives would hold up against these tests. Even though I had been careful with the design and the calculations I felt a little trepidation about what these tests would reveal. After I had a chance to inspect the test samples I gave the go ahead for the testing to begin.

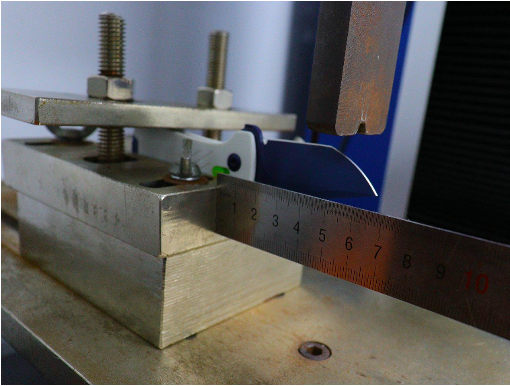

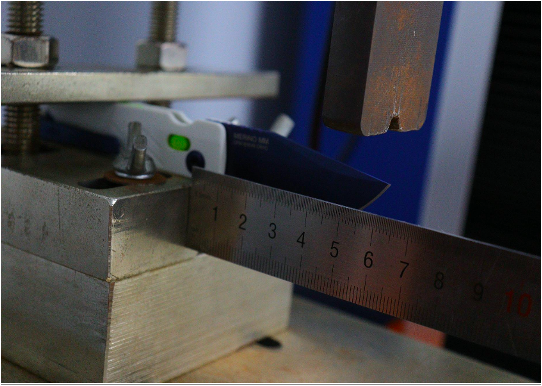

From edge retention to flexure to torsion, test after test these knives not only passed the tests but exceeded expectations. Finally, the last test was the lock strength test. This test would be conducted until the lock was broken. As the pressure rose higher and higher on my svelte knife I could feel the excitement in the room grow. When the lock finally broke there was an audible hush as the technician acquired the final results. To the amazement of the factory staff my thin knives had a lock strength of almost a magnitude more than the requirement of the factory's knife standard. The lock strength on the MM and DM models was about 900 lbf.

While shaking my hand they told me they didn’t think it was possible to have such a strong knife that was so thin and light but now they had no doubt.